The conversation around 5G has shifted. It’s no longer just about faster smartphones; it’s about reshaping entire industries. In the demanding world of industrial operations, where a millisecond of latency or a single data packet lost can cost thousands, the right connectivity isn’t a luxury—it’s the central nervous system. This is where industrial-grade 5G routers, like Levinlink’s solution for long-distance, large-data transmission, move from being a technical spec to a strategic asset.

The Industrial Demand: More Than Just “Fast Internet”

Modern industrial environments—smart factories, remote wind farms, autonomous guided vehicles (AGVs)—have connectivity needs that public 4G and Wi-Fi simply cannot reliably meet.

- Reliability is Non-Negotiable: Production lines cannot halt because of a network dropout. Industrial 5G routers are built with features like dual-SIM failover, ensuring if one carrier’s signal drops, the device instantly switches to another without interrupting data flow.

- Massive Data Hunger: High-definition video for quality control, LiDAR scans from drones, and constant telemetry from hundreds of sensors generate terabytes of data. This requires the high-bandwidth capacity of 5G to be transmitted in real-time, enabling actionable insights and predictive maintenance.

- The Need for Ruggedness: These devices operate in environments with extreme temperatures (-35°C to 75°C), vibration, and significant electromagnetic interference. Consumer-grade hardware would fail in minutes.

Why a Specialist Router Like the Levinlink Solution Makes Sense

A standard off-the-shelf router is a liability in an industrial setting. A purpose-built 5G industrial router addresses the core challenges head-on:

- Solving the “Last Mile” Problem: Running fiber to a remote oil pipeline or a moving mining vehicle is impossible. A powerful 5G router creates a reliable, high-speed wireless “last mile,” bridging the gap between remote assets and central cloud platforms.

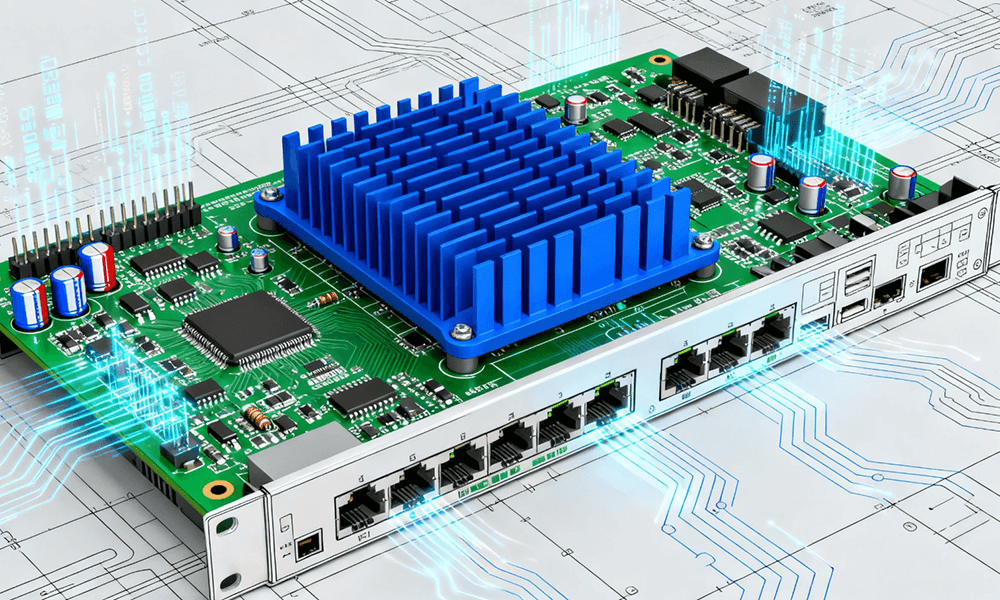

- Security as a Foundation: Industrial systems are critical infrastructure. With built-in VPN tunnels (IPsec, OpenVPN), all data transmitted between the field and the control center is encrypted, creating a secure private network over the public 5G spectrum.

- Seamless Integration with Legacy Systems: The inclusion of serial ports (RS232/485) and multiple LAN ports is crucial. It allows the router to connect to and modernize existing PLCs, sensors, and SCADA systems without a costly overhaul.

Connectivity as a Competitive Advantage

For businesses, the question is no longer if they should adopt advanced industrial IoT, but how. The foundation of any successful implementation is resilient, secure, and high-throughput connectivity.

Investing in a robust 5G industrial router isn’t just about buying a piece of hardware. It’s about:

- Enabling Automation: Unlocking the potential of real-time control for AGVs and automated machinery.

- Minimizing Downtime: Predictive maintenance and instant remote diagnostics keep operations running.

- Making Data-Driven Decisions: Harnessing the full volume of operational data without compromise.

In the new industrial landscape, your network is your lifeline. Choosing the right tool for the job isn’t just smart—it’s essential for staying competitive.