Introduction: 5G and the New Industrial Paradigm

The acceleration of digital transformation across industries has reshaped expectations for connectivity, automation, and data intelligence. As organizations pursue real-time responsiveness and large-scale IoT deployments, the integration of 5G and edge computing emerges as a fundamental enabler. At the center of this architecture is the smart gateway, which connects field devices, aggregates data, and provides computing capabilities at the edge. Its role continues to expand as industries shift toward autonomous, distributed, and interconnected systems.

The Real-World Drivers Behind 5G Adoption

The rapid development of 5G is not purely technological—it is driven by practical industrial needs that legacy networks cannot meet. Key forces include:

Increasing Device Density in IoT Environments

Modern industrial facilities deploy thousands of sensors, controllers, and smart devices. Traditional wireless systems struggle with congestion and interference, while 5G supports massive machine-type communication (mMTC) with high reliability.

Demand for Ultra-Low Latency

Applications such as autonomous mobile robots (AMRs), machine vision inspection, and real-time control loops require latency below 10 ms. 5G URLLC capabilities are specifically designed for these mission-critical operations.

Need for Higher Bandwidth and Stability

High-resolution cameras, predictive maintenance models, and energy monitoring platforms generate continuous data streams. Enhanced mobile broadband (eMBB) allows stable, high-throughput communication across industrial sites.

Comparison of Industrial Connectivity Needs and 5G Capabilities

| Industrial Requirement | Traditional Networks | 5G Capability |

|---|---|---|

| Device Density | Limited | Massive IoT support |

| Latency | 30–100 ms typical | <10 ms (URLLC) |

| Reliability | Medium | 99.999% |

| Bandwidth | Moderate | High throughput |

| Mobility | Low | High mobility |

What Is Edge Computing?

Edge computing is a distributed computing framework that processes data near its source rather than relying solely on cloud-based systems. In industrial environments, this approach reduces latency, enhances security, and ensures operational continuity even during network disruptions.

Key Characteristics of Edge Computing

- Localized Data Processing: Reduces cloud dependency and response time.

- Improved Security: Keeps sensitive operational data on-site.

- Bandwidth Optimization: Limits unnecessary data transmission to the cloud.

- Autonomous Operation: Enables systems to continue functioning without central connectivity.

Devices Required for Edge Deployment

Edge implementations typically include:

- Smart Gateways for protocol conversion, data aggregation, and AI inference.

- Industrial Controllers capable of containerized application deployment.

- Edge Servers providing computational power for analytics and machine learning.

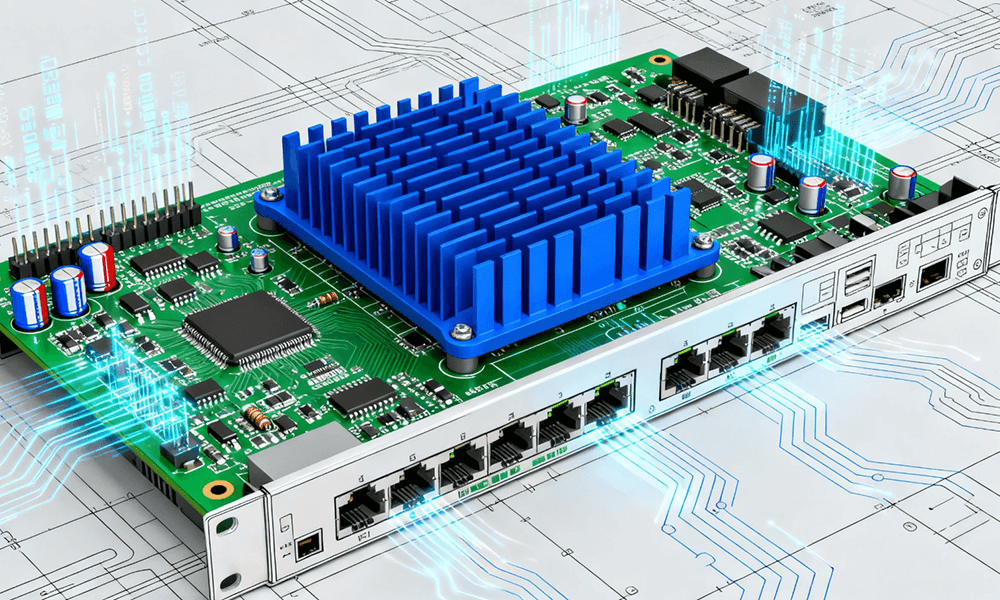

The Role of Smart Gateways and Ethernet Switches in 5G Architectures

As industries adopt 5G-enabled infrastructures, both smart gateways and Ethernet switches become essential components.

Smart Gateways as the Intelligent Edge Node:

A modern smart gateway functions as:

- A bridging device between OT and IT networks.

- A real-time analytics engine for edge processing.

- A multi-protocol translator supporting Modbus, CAN, Profinet, MQTT, and more.

- A local decision-making point capable of AI inference.

By integrating 5G modules, smart gateways offer wireless flexibility, high mobility, and strong backhaul performance.

Ethernet Switches as the Deterministic Backbone

While 5G enables wireless expansion, Ethernet switches remain critical for deterministic industrial communication.

They provide:

- Wired stability for PLCs, sensors, and controllers.

- Time-sensitive networking (TSN) capabilities for precise synchronization.

- Network segmentation for improved security and reliability.

Combining Wired and Wireless Systems

A hybrid architecture using both 5G and Ethernet switches allows industries to:

- Maintain wired reliability where timing is critical.

- Deploy wireless mobility for AGVs, sensors, and mobile robots.

- Scale IoT systems without physical cable limitations.

Conclusion

The rise of 5G and edge computing marks a pivotal shift in industrial connectivity. Smart gateways and Ethernet switches play complementary roles—one enabling flexible, intelligent edge processing, the other providing stable and deterministic wired networks. Together, they form the backbone for real-time, autonomous, and distributed industrial systems.