Mine safety is at the heart of modern smart mining initiatives. With the complexity of underground operations and the presence of risks like toxic gas, high humidity, poor visibility, and heavy machinery, there’s a growing need for a robust monitoring system that offers real-time awareness, early detection, and efficient emergency response. This solution provides a reliable safety infrastructure for both underground and surface operations, helping mining companies build safer, smarter, and more efficient mines.

Mine Safty Monitoring System Requirements and Architecture

Coal mining often takes place in extreme environments where conditions such as dust, heat, gas concentration, and confined workspaces challenge both workers and equipment. These factors demand a rugged, intelligent monitoring solution.

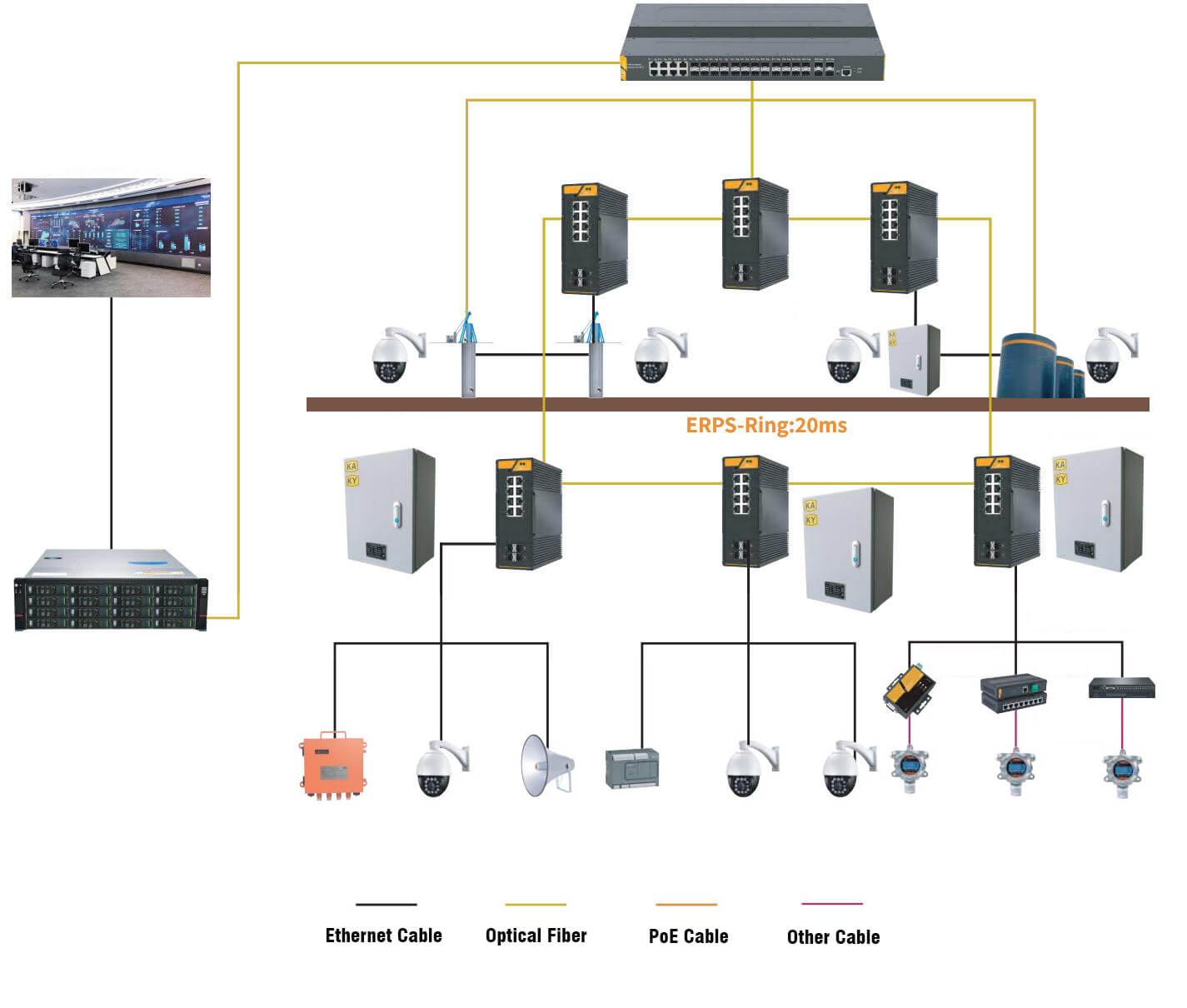

Our system is designed to support high-stress environments through a combination of industrial-grade sensors and intelligent cameras that gather and transmit real-time data. Both underground and surface levels are connected via a dual-layer network made up of fiber-optic and wireless communication technologies. The entire infrastructure is built for stability and scalability, offering strong environmental adaptability and data reliability.

Key Features of the Mine Safty Monitoring System

To keep the system clean and scannable, we’ve kept a single enhanced list format for key technical features:

- Integrated sensing and video surveillance, with real-time tracking of gas levels, temperature, humidity, and air pressure.

- Industrial-grade communication backbone, using fiber-ring and wireless mesh networks for underground and surface data transfer.

- Mobile response tools, including helmet-mounted cameras and handheld units for rapid deployment during inspections or emergencies.

- Remote monitoring and alert interface, using SNMP and web platforms to visualize, analyze, and respond to any abnormal readings.

Platform and Operational Control

The entire system is managed through a dual-layer platform. Underground data nodes collect all sensor and video inputs and relay them to the surface-level control center. There, operators can access a centralized dashboard to monitor conditions in real time, receive alarm notifications, generate safety reports, and coordinate emergency responses.

The system supports 24/7 operation and is designed for low power consumption and high fault tolerance. With real-time diagnostics and remote accessibility, managers can optimize workflows while maintaining full situational awareness of the mining site.

Smart Mine Environmental & Safety Monitoring Diagram

Dispatching Command Center Main Shaft Hoisting System SH-GM0408 Substation/Working Face Surface Optical Fiber Ring Network Processing Warehouse SH-6808 SH-6616 SH-6311M Safety Detection System Personnel Positioning System Camera Broadcast PLC Controller Monitor Server Core Switch Ring Network Switch Serial Server SH-GMR481600 SH-GM0408

Dispatching Command Center Main Shaft Hoisting System SH-GM0408 Substation/Working Face Surface Optical Fiber Ring Network Processing Warehouse SH-6808 SH-6616 SH-6311M Safety Detection System Personnel Positioning System Camera Broadcast PLC Controller Monitor Server Core Switch Ring Network Switch Serial Server SH-GMR481600 SH-GM0408Industrial-Grade Mine Safty Devices Supporting Mine Safety

Enhancing Mine Safety Through Intelligent Monitoring

This integrated monitoring system not only meets current safety regulations, but also improves operational efficiency. By combining intelligent sensing, environmental data analysis, and centralized command tools, mining operations can reduce on-site hazards, automate risk detection, and streamline communication between underground and surface teams.

The result is a safer, more responsive working environment that supports long-term sustainability and aligns with evolving mine safety standards.