The wind power industry demands intelligent and reliable systems to monitor turbine performance in real time. By implementing a redundant ring network using industrial Ethernet switches, each turbine in the wind farm is interconnected to form a highly available and secure infrastructure. This setup supports remote data collection, fault alarms, and centralized control via SCADA systems. Integrated with IoT technologies, this system ensures efficient communication between turbines and the control center, enabling predictive maintenance and operational transparency.

Deployment Strategy for Wind Power Monitoring

The primary objective is to create a robust communication network for the wind power site that enables real-time data collection, adaptive control, and early warning capabilities. Each turbine is equipped with a generator, PLC, and industrial PC, which communicate environmental and operational data such as wind speed, blade angle, and generator load. This allows for automated blade adjustments and generator speed regulation to maximize energy output and system safety.

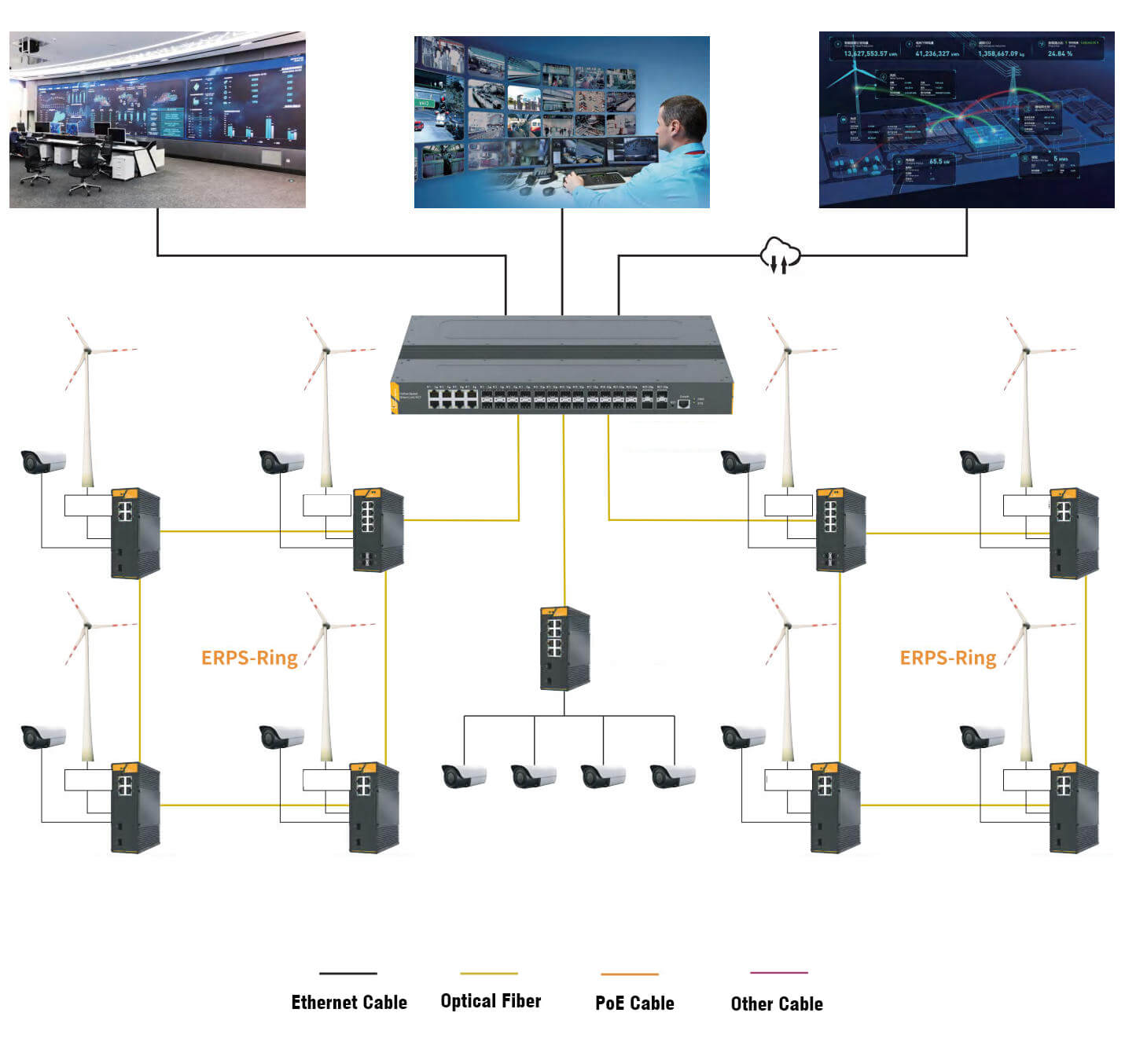

To meet the demands of geographically dispersed turbines, we deploy an ERPS-ring (<20ms) topology using industrial-grade switches. This design supports IoT-based monitoring and ensures reliable, low-latency communication across star, ring, or hybrid topologies. The network also integrates seamlessly with centralized SCADA platforms for smart visualization and event management.

Key Features and IoT Integration in Wind Power Systems

- Real-Time Data Transmission:

Collects key turbine data (wind speed, temperature, generator RPM, etc.) and transmits it in real-time for centralized monitoring and automated decision-making. - Intelligent Fault Detection:

Supports IoT-driven diagnostics and alert systems, providing instant notifications for abnormal conditions like blade imbalance or overheating. - Modular Network Design:

Utilizes LevinLink’s modular industrial Ethernet switches, supporting flexible deployment across ring or star topologies based on terrain complexity. - Ruggedized Hardware:

Operating range from -40°C to +85°C, with IP40-rated enclosures and multi-port configurations tailored for harsh environments. - Global Certifications:

Complies with CE, FCC, UL, and national grid standards, including testing by the State Grid Electric Power Research Institute in China. - Future-Proof with IoT Integration:

The system architecture is fully compatible with Industrial IoT (IIoT) platforms, enabling seamless expansion to include weather stations, smart sensors, and predictive analytics.

Application Topology Diagram

Power Control Center Video Surveillance System Cloud Management Platform Industrial Switch PLC PLC Industrial Switch Industrial Switch PLC PLC PLC PLC PLC PLC Industrial Switch Industrial Switch SH-GM0204 Industrial Switch Industrial Switch Industrial Switch Industrial Switch Core Switch Perimeter Monitoring Wind Farm A Wind Farm B Cloud Acceleration Security Camera SH-GMR481600 SH-GM0204 SH-GM0204 SH-GM0204 SH-GM0204 SH-GM0204 SH-GM0208 SH-GM0408 SH-GM0408

Power Control Center Video Surveillance System Cloud Management Platform Industrial Switch PLC PLC Industrial Switch Industrial Switch PLC PLC PLC PLC PLC PLC Industrial Switch Industrial Switch SH-GM0204 Industrial Switch Industrial Switch Industrial Switch Industrial Switch Core Switch Perimeter Monitoring Wind Farm A Wind Farm B Cloud Acceleration Security Camera SH-GMR481600 SH-GM0204 SH-GM0204 SH-GM0204 SH-GM0204 SH-GM0204 SH-GM0208 SH-GM0408 SH-GM0408